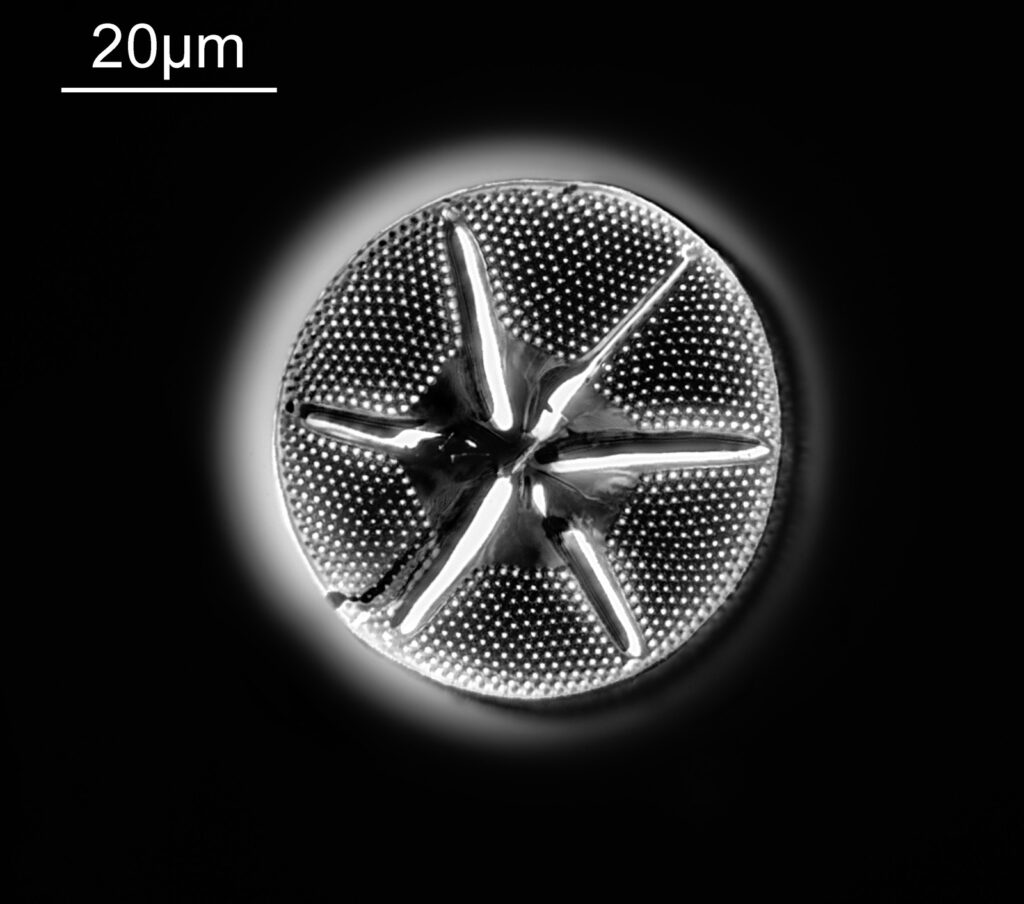

Metalizing slides of diatoms to boost contrast is a technique which has been around for over 100 years, and variations on the technique still live on today. Probably the most well known practitioner was Horace Dall (an optical genius and someone I’ve written about before on this site), however the slide maker John Dale is also known for making high quality aluminium coated diatom slides. Today’s post share a few images from one of his slides which recently arrived.

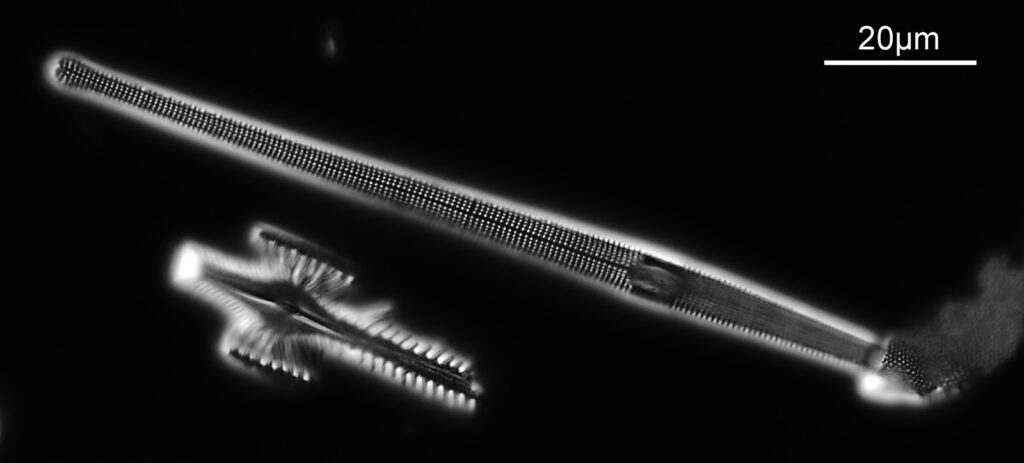

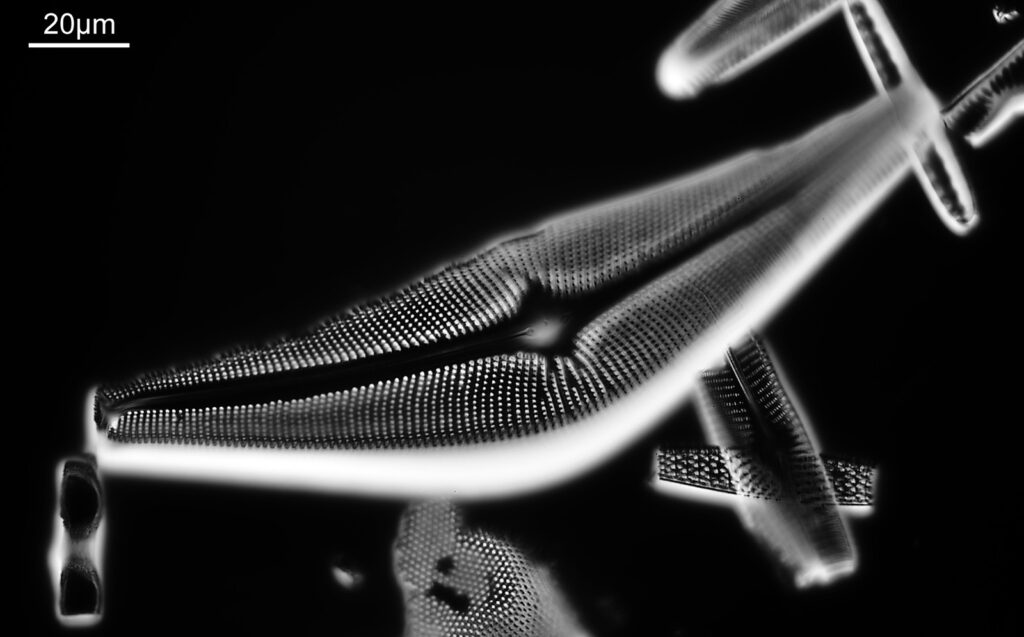

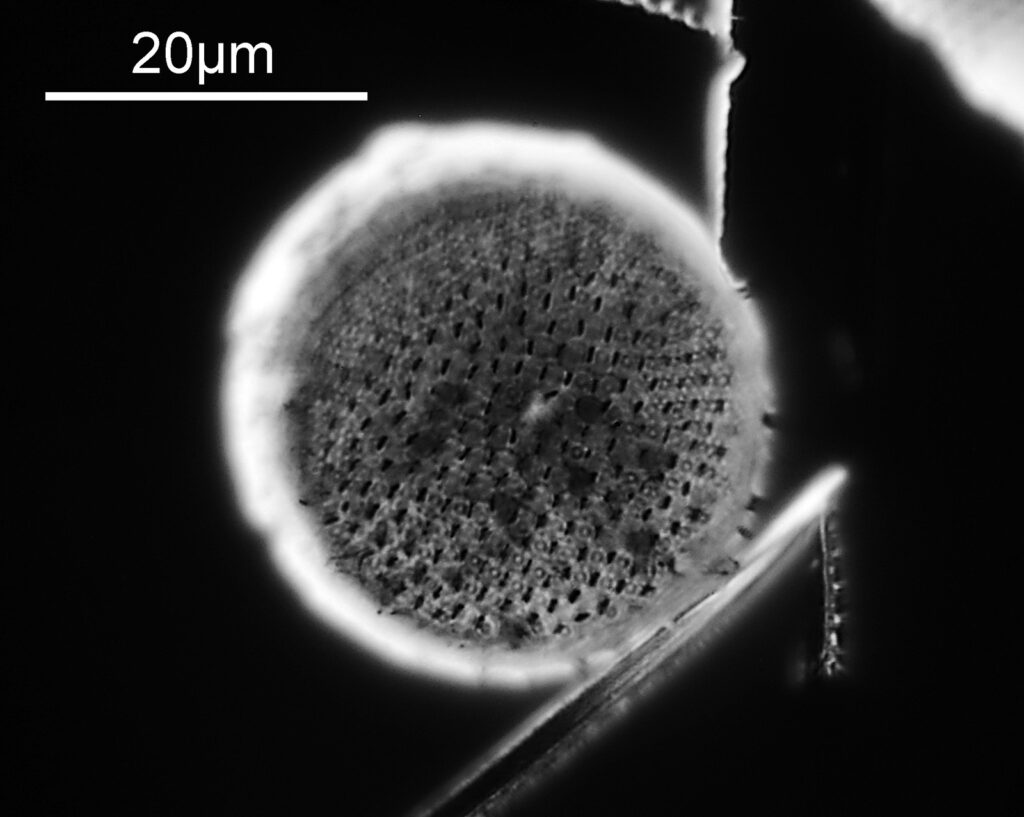

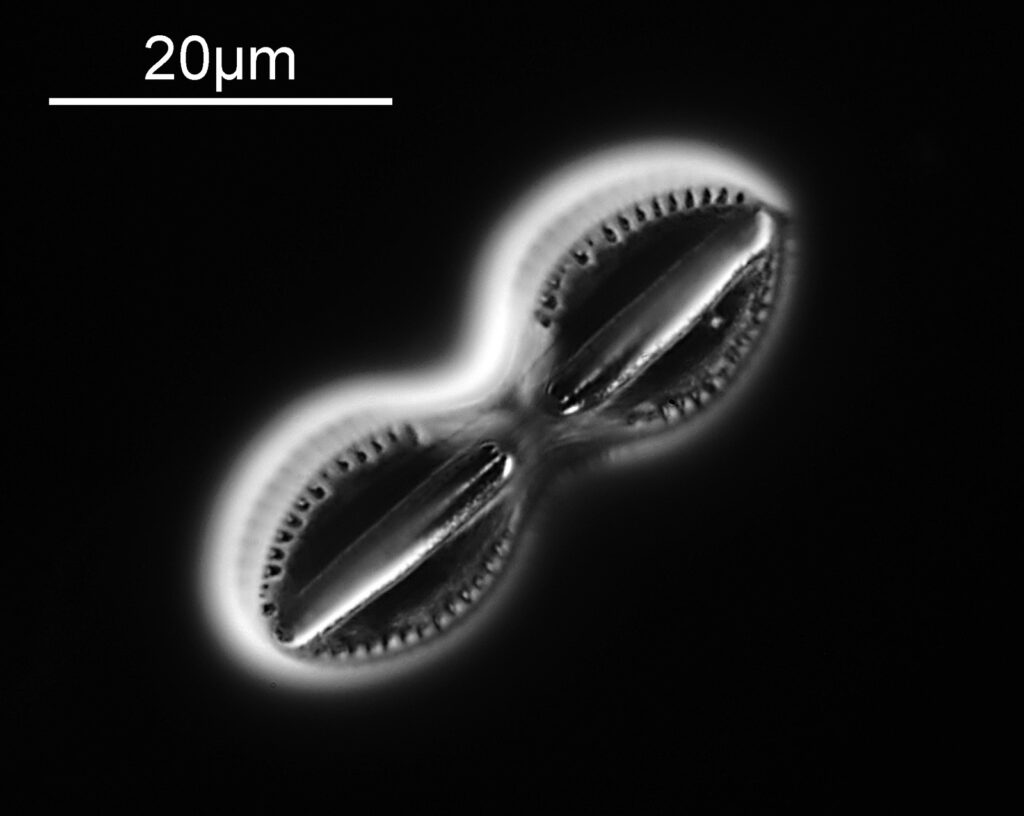

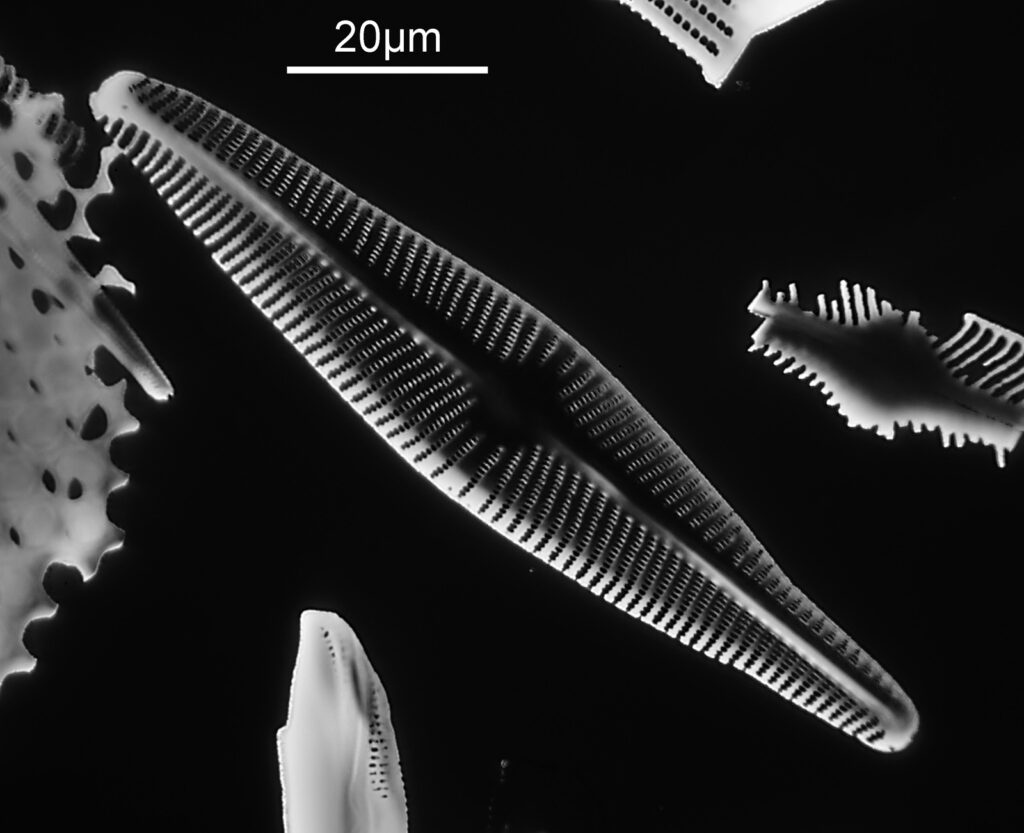

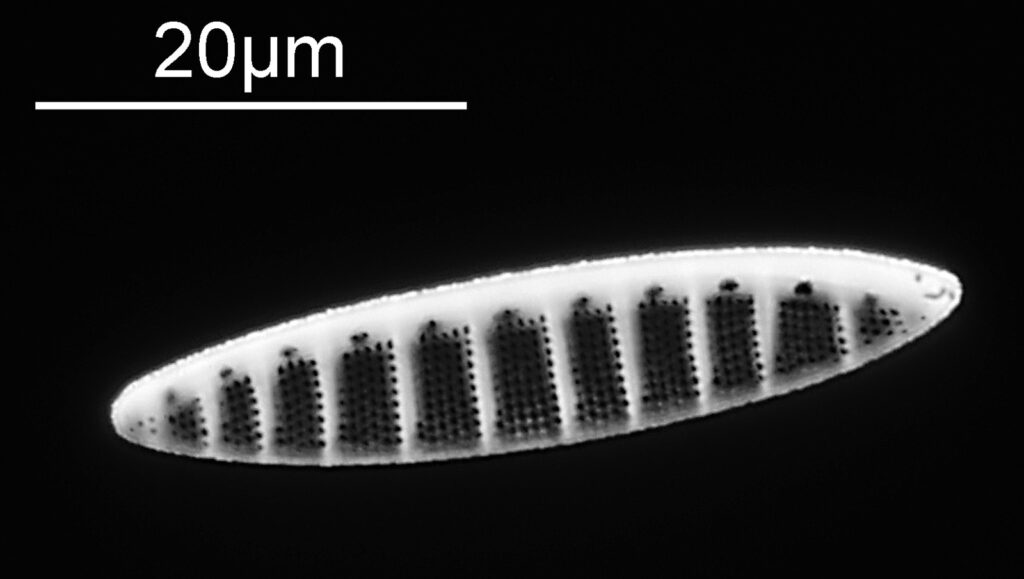

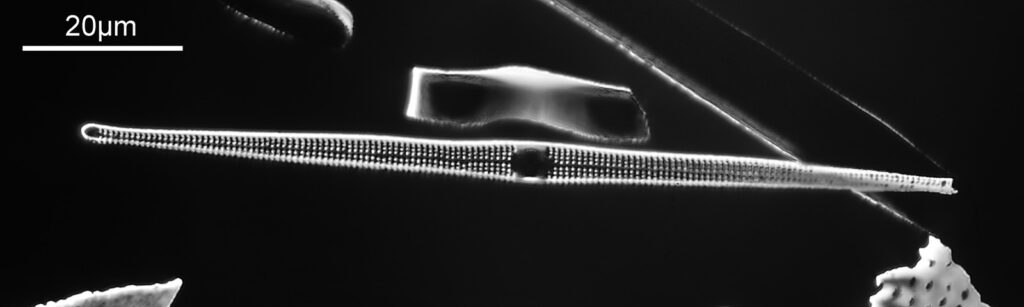

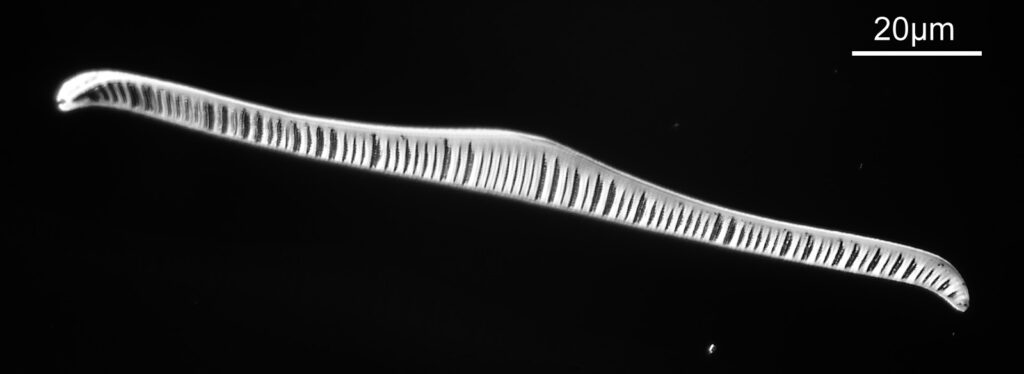

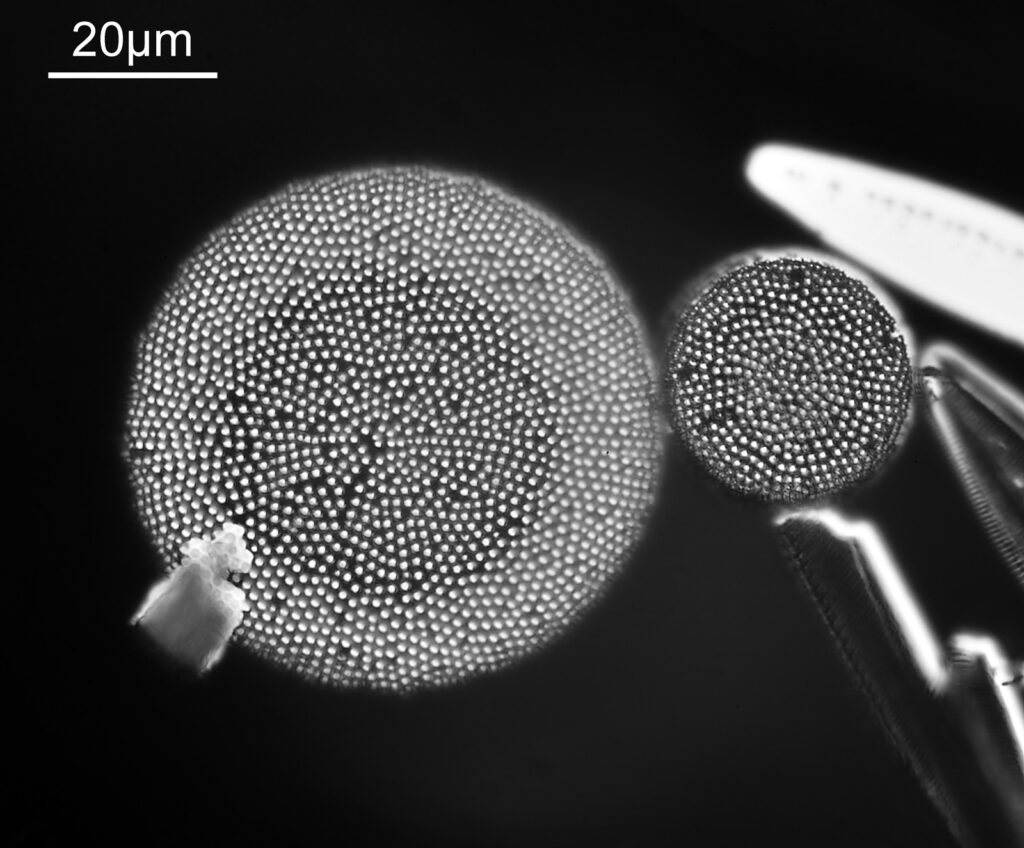

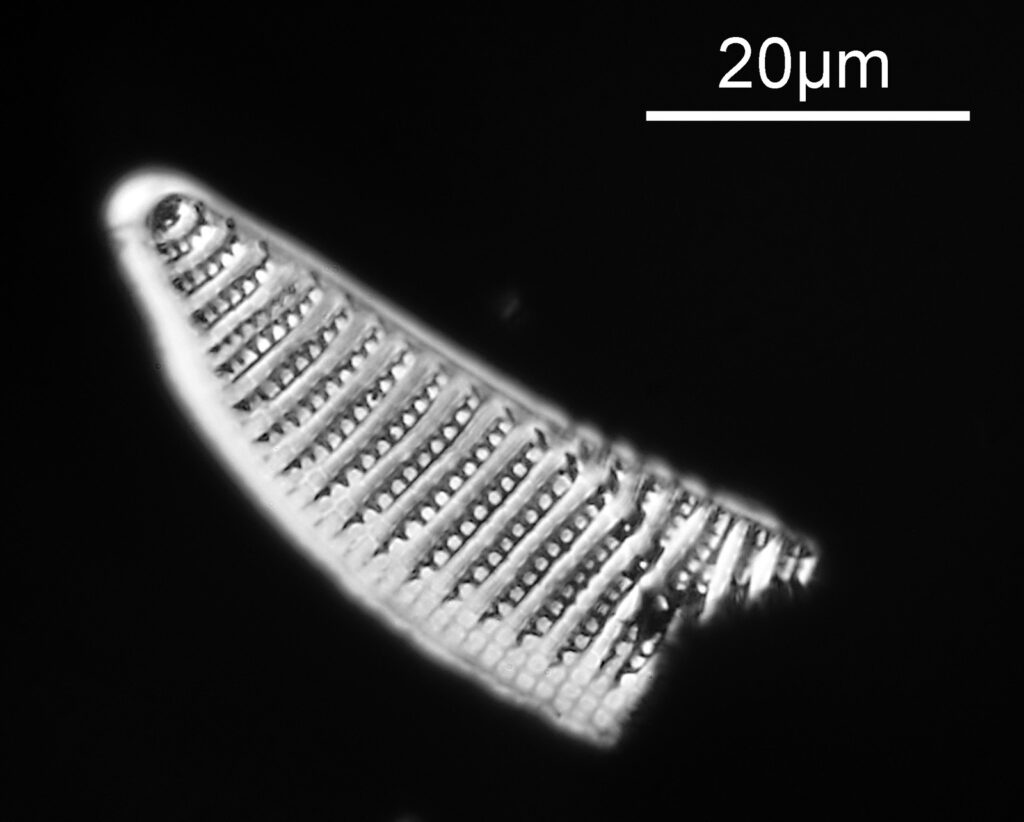

All images were done using my modified Olympus BHB microscope, using 450nm LED light. a 63x Leitz Pl Apo NA 1.40 objective was used with oil immersion. The condenser was an Olympus Aplanat Achromat, oil immersion, set to normal brightfield (more on that later, as these images do not look like standard brightfield ones). 2.5x Nikon CF PL photoeyepiece. Monochrome converted Nikon d850 camera. Images have been reduced in resolution for sharing here, which is a pity given the amazing resolution slide slide offered, but if I don’t do that, my available storage rapidly disappears. Most are single images, but a couple are stacks.

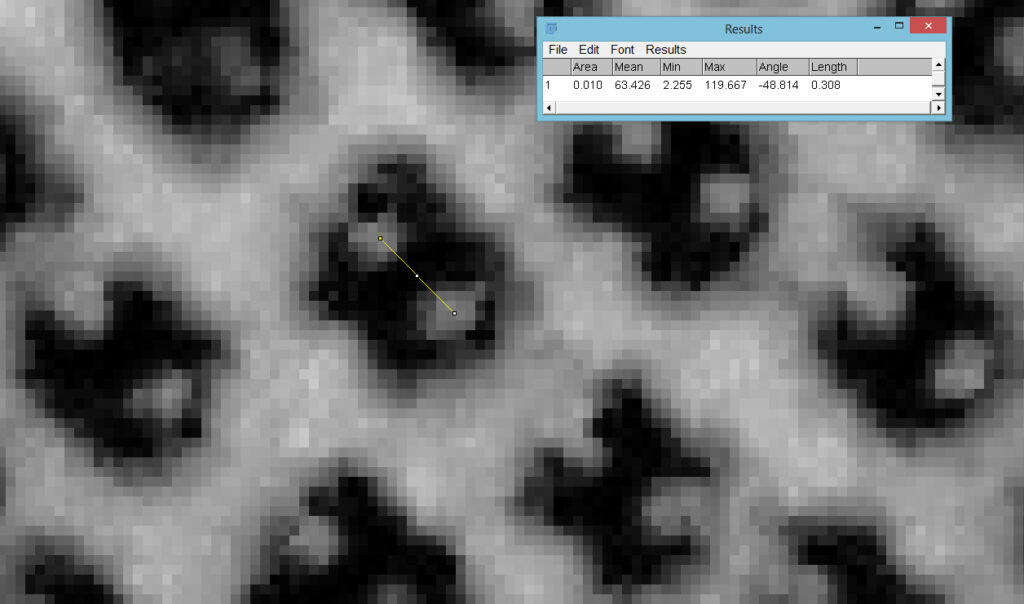

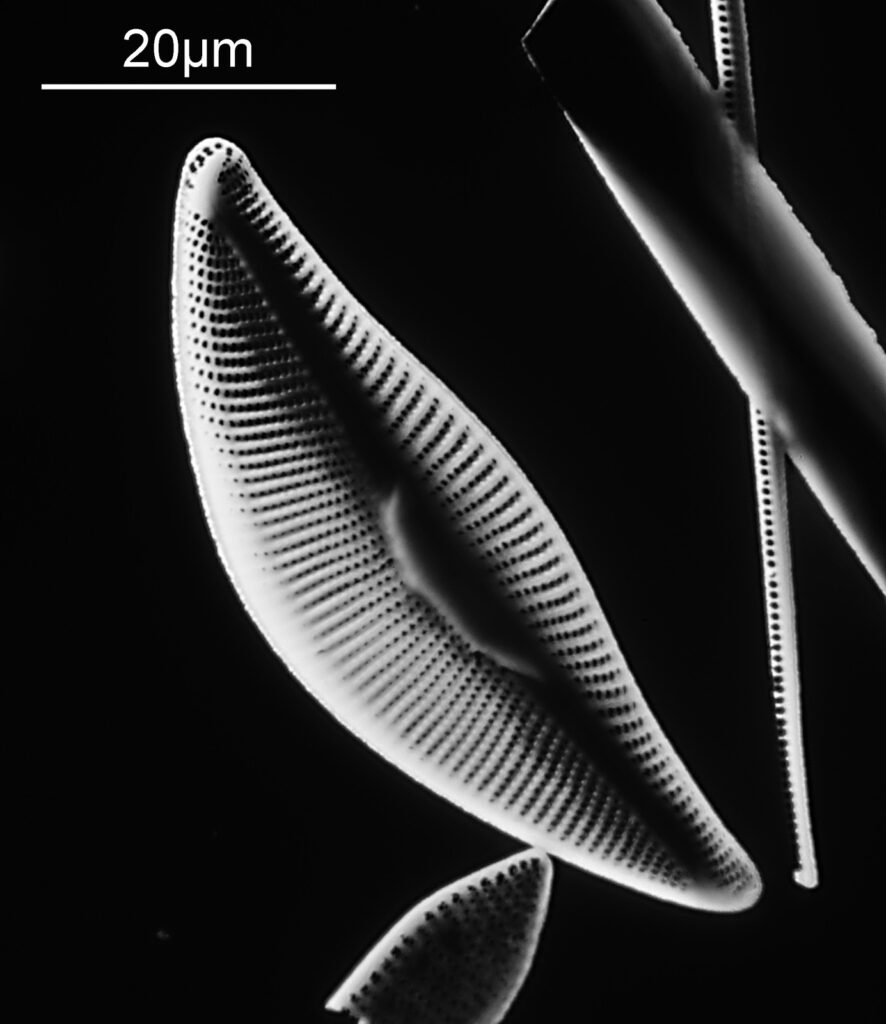

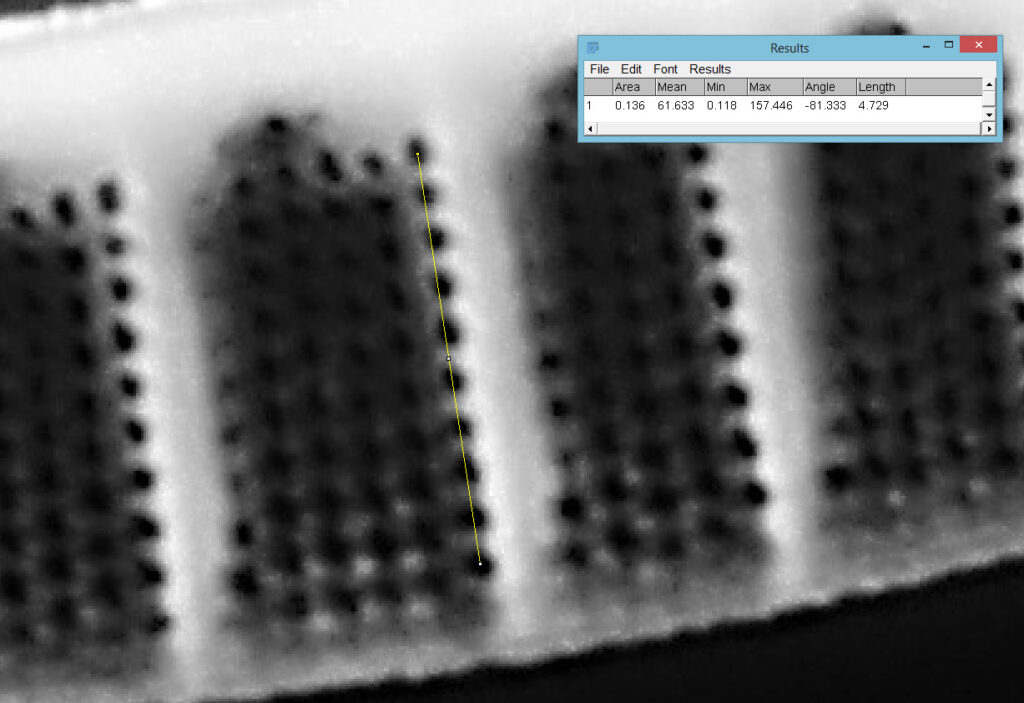

If we go in close to the image above, inside the black dots, are two light ones. These are about 308nm apart (thank you ImageJ)!!

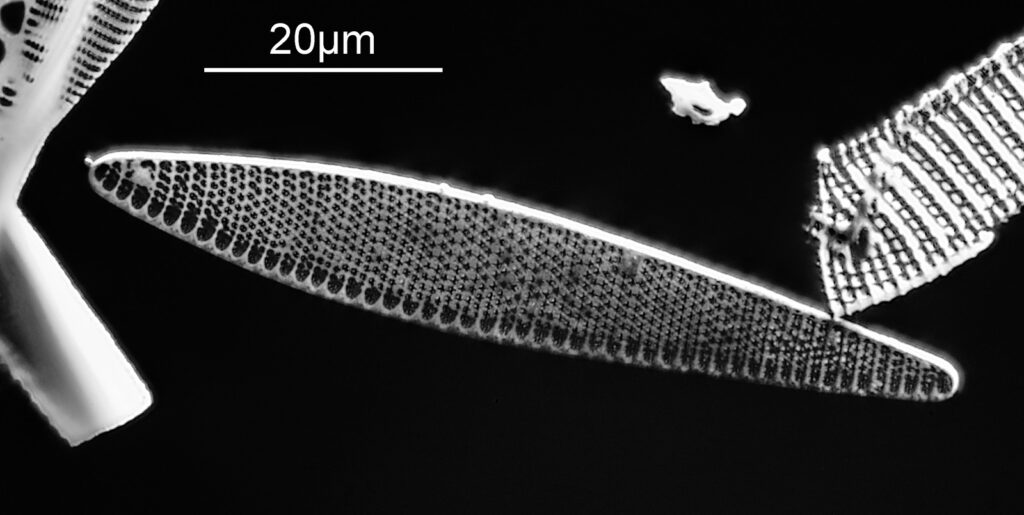

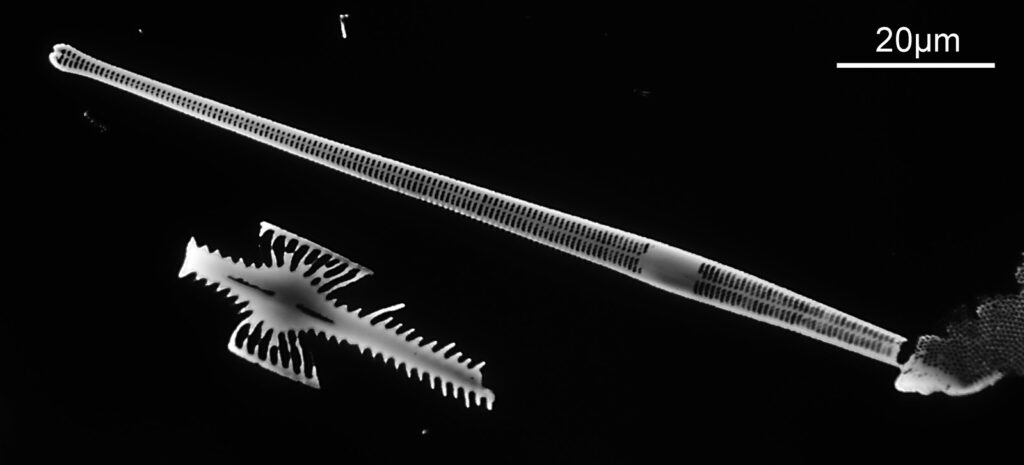

Again, looking at the image above in ImageJ gives a spacing of about 525nm between the black dots.

And, as always, the slide.

The images above were collected using a brightfield setup, but they look more like dark field ones. What is going on here? A thin layer of a few nm of aluminium has been deposited over the diatoms. This effectively makes flat areas such as the bare glass opaque. As the diatoms have holes in them when the aluminium is deposited parts of the diatom go opaque but the light can still get through the holes. What you end up with when imaged from below is a high contrast image with a dark background.

A fascinating technique and just about doable at home if you have the right kit and expertise. As always thanks for reading, and if you’d like to know more about my work, I can be reached here.